Flexco recently announced the addition of the Belt Support Bar (BSB) to its line of Heavy-Duty belt support system tools. Once installed onto a facility's conveyor belt, the BSB immediately creates a better seal, mitigating the release of dust and creating a more efficient and safer belt conveying process.

“The Belt Support Bar is a much-needed addition to our collection of conveyor belt support systems,” said Flexco Product Manager Kevin Fales. “During site visits, our territory managers often notice idlers in the conveyor load zone that are either installed so close together that they become difficult to impossible to service, or installed too far apart, causing the belt to sag. Unfortunately, this can create significant issues for plant managers, as when their belts are unsupported, their skirting system cannot properly seal, letting dust or material leak out. The material pileup that is created is hazardous to work around, often requiring physical labor to clean-up, and causes other components like the belt, idlers, or pulleys to become susceptible to excess wear. Worse, the release of dust subjects their onsite workforce to dust exposure that can be dangerous for their long-term respiratory health. By utilizing our new Belt Support Bar, operators can effectively flatten and seal their belts, mitigating these negatives effects and helping to reduce potential downtime incidents.”

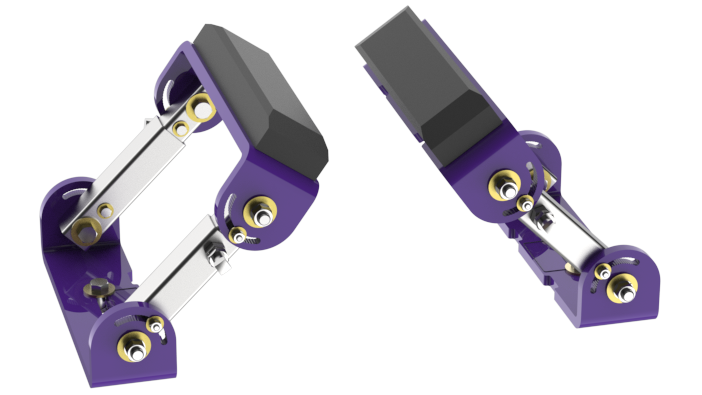

With its simple installation process, the BSB allows installation crews to leave the belt in place during setup, altogether avoiding the complications that arise when using a different Heavy-Duty support system like impact bars that may require a team to lift the belt and completely remove the prior system during installation. Instead, the BSB easily bolts onto the frame of the conveyor structure between idlers, is pushed in place to hold the belt up, and is finally bolted in place to create an effective seal and flattened belt. The Belt Support Bar product design is patented, giving Flexco’s partner network the exclusive ability to quickly bolt their support system between their idlers and push it up into their conveyor belt for added support.

The BSB is available for belt widths ranging from 18” (450mm) to 96” (2400mm), and in trough angles of 20°, 35°, and 45°. Additionally, the BSB can operate under a maximum belt speed of 1000 FPM (5 M/sec), works with temperatures ranging from -20 to 180°F (-28 to 82°C), and requires a horizontal clearance of 16 to 30'' (406 to 762mm).

The Flexco Belt Support Bar can be used in Heavy-Duty applications within industries like aggregate, cement, coal, open pit/hard rock mining, and underground mining.

For more information on the Flexco Belt Support Bar or any other heavy-duty belt conveyor solutions from Flexco, log onto www.flexco.com.