Industry

Hard Rock Mining

Application

Conveying raw ore out of primary crusher

Product

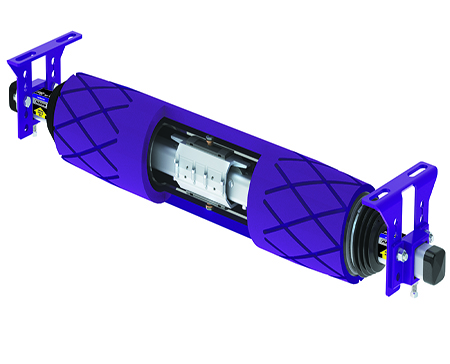

PTEZ™ HD Belt Trainer

Objective

Eliminate mistracking

Extend belt life

Conveyor Detail

60”-wide belt, 2000 PIW steel cable, running at 400 fpm

Problem:

Space limitations were a big issue when it came to tackling a mistracking belt at a Midwest mining operation. The trainer they were using to try to bring the belt back to center was not effective, causing the belt to rub hard enough against the steel conveyor structure that it would damage the belt and eventually rupture the steel cables. The area they were most concerned about was located approximately 200 feet before the drivehouse on the return side of the belt. Because of the tight nature of the area, trainers they used on other parts of the belt simply wouldn’t fit.

Solution:

This operation experienced previous success with nine Flexco PT Max™ Belt Trainers located throughout the facility. This positive experience led the maintenance supervisor to contact Flexco for solutions to this problem. After evaluating the application, Flexco recommended the PTEZ™ HD Belt Trainer. Developed for return-side mistracking, the PTEZ HD is designed to handle tough mining conditions, utilizing pivot-and-tilt technology to track the belt without the use of sensor rollers.

Result:

Not only was the PTEZ a good fit in the tight space because of its small footprint; it also performed well. The PTEZ HD was more effective than the trainer it replaced, and did not damage the ends of the belt like other trainers had done. The PTEZ HD is also rugged enough to handle the abrasive application, featuring urethane lagging for exceptional wear life over conventional rubber lagged trainers.